Electric motors play a crucial role in powering robotic systems, providing the precision, efficiency, and performance needed for diverse applications. As robotics evolves across industries, the demand for specialized motors continues to grow. From manufacturing to healthcare, these motors enable seamless operation and functionality. Let’s explore why choosing the right electric motor for robotics is vital and how it drives innovation in the field.

Why Electric Motors Are Essential in Robotics

The effectiveness of any robotic system depends heavily on its motor.

Electric motors convert electrical energy into mechanical motion, enabling robots to perform specific tasks with precision. They determine a robot’s speed, torque, and efficiency, directly impacting its overall performance. The versatility of these motors allows their integration into various robotic applications, from lightweight drones to heavy-duty industrial arms.

Key Features of an Electric Motor for Robotics

Motors designed for robotics come equipped with features tailored for optimal performance.

High Torque-to-Weight Ratio

Motors with a superior torque-to-weight ratio enhance power without adding unnecessary bulk, crucial for mobile and lightweight robots.

Precision Control

Advanced motors allow for precise positioning and movement, essential for tasks like surgical robotics or intricate assembly lines.

Energy Efficiency

Efficient motors minimize energy consumption, extending battery life in mobile robots or reducing operational costs in industrial systems.

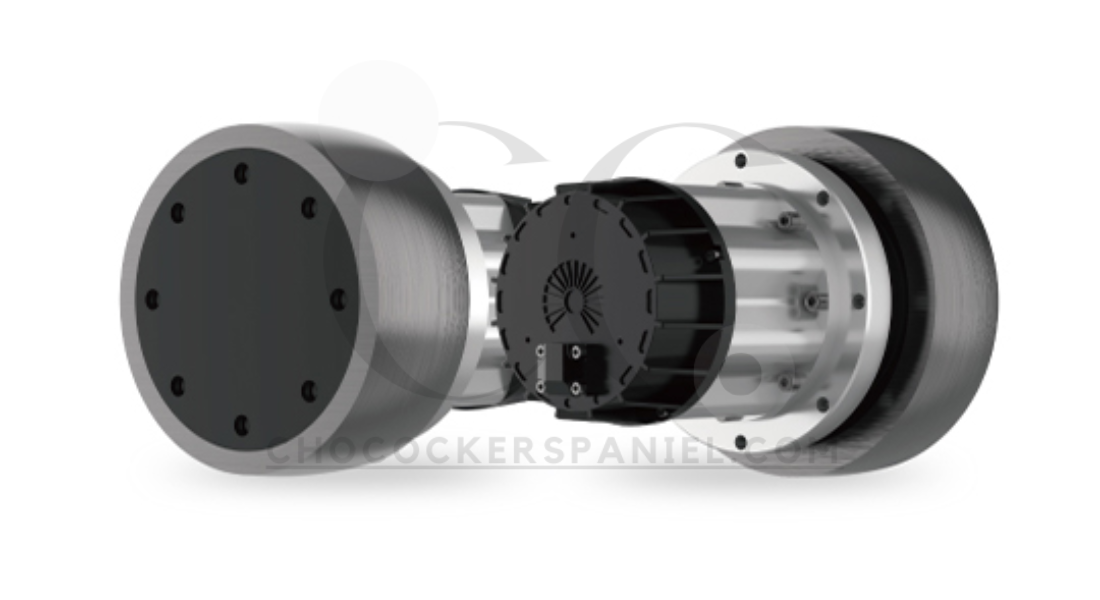

Compact Design

Space-efficient motors fit seamlessly into robots, preserving functionality while maintaining a sleek profile.

Durability

Motors built for robotics withstand demanding environments, ensuring long-term reliability in applications like mining or underwater exploration.

Types of Electric Motors Commonly Used in Robotics

Different types of electric motors cater to varying robotic needs.

1. DC Motors

- Advantages: Simple design, easy control, and cost-effectiveness.

- Applications: Ideal for small robots requiring continuous rotation, like toy robots or basic mobile platforms.

2. Brushless DC Motors (BLDC)

- Advantages: High efficiency, quiet operation, and low maintenance.

- Applications: Frequently used in drones, robotic arms, and precision-guided systems.

3. Stepper Motors

- Advantages: Precise control over incremental movements.

- Applications: Suitable for 3D printers, CNC machines, and pick-and-place robots.

4. Servo Motors

- Advantages: Accurate position control and high torque.

- Applications: Essential in industrial robots and robotic manipulators requiring intricate movements.

Choosing the Right Electric Motor for Robotics

Selecting the right motor requires careful consideration of the robot’s purpose and operating conditions.

Define the Application

Understand whether the robot needs continuous rotation, precise positioning, or high-speed movement.

Assess Torque and Speed Requirements

Determine the level of torque and speed necessary for the robot to perform its intended tasks effectively.

Consider Space Constraints

Ensure the motor’s size aligns with the robot’s design and available space.

Evaluate Power Needs

Opt for energy-efficient motors to maximize battery life or reduce operational costs.

Factor in Environment

Choose motors designed to withstand specific environmental conditions, such as high temperatures or exposure to water.

Applications of Electric Motors in Robotics

Electric motors drive innovation in various robotic applications, spanning industries and tasks.

1. Industrial Automation

Motors power robotic arms used for welding, assembly, and material handling, enhancing precision and efficiency in factories.

2. Healthcare Robotics

Medical robots rely on motors for tasks like minimally invasive surgery, patient assistance, and rehabilitation therapy.

3. Agricultural Robots

From autonomous tractors to crop-monitoring drones, motors facilitate smarter farming practices.

4. Humanoid Robots

Sophisticated motors enable human-like movements in robots designed for customer service, entertainment, or caregiving.

5. Drones and Autonomous Vehicles

Lightweight and efficient motors provide the propulsion and control needed for flight and navigation.

6. Exploration and Research

Motors help power robots designed for space exploration, underwater research, and disaster response.

Advancements in Electric Motor Technology for Robotics

Innovations in motor technology continue to push the boundaries of what robots can achieve.

1. Improved Energy Efficiency

Motors now consume less energy while delivering higher performance, reducing operational costs.

2. Miniaturization

Smaller motors with higher power output allow for compact and lightweight robotic designs.

3. Smart Motors

Integrated sensors and feedback systems enable motors to self-monitor and adapt to changing conditions.

4. High-Performance Materials

Advanced materials enhance motor durability and reduce wear, improving long-term reliability.

5. Integration with AI

Motors designed to work with AI algorithms optimize performance, enabling smarter and more autonomous robots.

Maintenance Tips for Electric Motors in Robotics

Regular upkeep ensures the longevity and efficiency of motors used in robotic systems.

Inspect Regularly

Check for wear and tear on components, such as bearings and brushes, to prevent unexpected failures.

Clean Periodically

Remove dust and debris from motors to maintain performance and prevent overheating.

Monitor Performance

Use integrated sensors to track motor efficiency and address any anomalies promptly.

Lubricate Moving Parts

Apply appropriate lubricants to reduce friction and extend the motor’s lifespan.

Protect from Extreme Conditions

Use enclosures or coatings to shield motors from harsh environments like moisture, dust, or extreme heat.

Benefits of Using Advanced Electric Motors in Robotics

Modern motors offer distinct advantages that enhance robotic functionality and efficiency.

Enhanced Precision

Motors with advanced control systems deliver highly accurate movements, essential for delicate tasks.

Greater Reliability

Robust designs ensure motors perform consistently, even in challenging conditions.

Scalability

Motors can be adapted for use in robots of varying sizes and complexities, from microbots to industrial giants.

Reduced Costs

Efficient motors lower energy consumption and maintenance expenses, providing long-term savings.

Broader Applications

Innovative motor designs expand the range of tasks robots can perform, driving versatility and innovation.

Future Trends in Electric Motors for Robotics

The future of motors in robotics looks promising, with advancements poised to redefine the industry.

1. High-Torque Miniature Motors

Motors will become smaller yet more powerful, enabling compact robots to perform heavy-duty tasks.

2. AI-Powered Motion Control

Artificial intelligence will enhance motor control, allowing for smarter and more adaptive movement.

3. Sustainable Motor Design

Eco-friendly materials and energy-efficient designs will align with global sustainability goals.

4. Wireless Power Transfer

Motors integrated with wireless charging technology will eliminate the need for physical connections, improving flexibility.

5. Modular Motors

Interchangeable motor modules will simplify robot customization and maintenance.

Challenges and Solutions in Motor Selection for Robotics

Choosing the right motor can present challenges, but solutions are available to address them.

High Power Demands

Solution: Use high-efficiency motors to balance power output and energy consumption.

Space Constraints

Solution: Opt for compact motor designs with advanced torque capabilities.

Environmental Factors

Solution: Select motors with protective coatings and robust enclosures for harsh conditions.

Integration with Other Systems

Solution: Choose motors compatible with standardized communication protocols and controllers.

Final Thoughts on Electric Motors for Robotics

Electric motors are the driving force behind the functionality and versatility of robotic systems. From enabling precision movements to ensuring energy efficiency, the right motor choice can make or break a robot’s performance.

Investing in advanced motor technology allows businesses to push the boundaries of innovation, creating robots that are smarter, faster, and more efficient. Whether in manufacturing, healthcare, or exploration, electric motors for robotics continue to play a central role in shaping the future of automation and technology.